Explore the fascinating world of Kaplan turbines, an essential component of hydroelectric power generation and renewable energy solutions. Developed by Austrian professor Viktor Kaplan in 1913, Kaplan turbines harness the power of water to produce electricity in an efficient and sustainable manner.

But how do these turbines work? Let’s delve into the intricate details of their functioning and discover the science behind their operation.

Before we dive into the technicalities, it’s important to understand that Kaplan turbines are specifically designed for sites with low head and high flow rates, making them ideal for hydroelectric power generation. Check also our information on Francis turbines here.

Main Components of Kaplan Turbine

A Kaplan turbine consists of several key components that work together to harness the power of flowing water and convert it into mechanical energy. These components include the scroll casing, guide vane mechanism, draft tube, and runner blades.

The scroll casing is a spiral-type casing that surrounds the inner workings of the turbine. Its main function is to protect the delicate internal parts, such as the runner blades and guide vanes, from external damage. The scroll casing also helps to control the flow of water through the turbine, ensuring that it passes through the runner blades with maximum efficiency.

The guide vane mechanism is another crucial component of the Kaplan turbine. It allows for the adjustment of the guide vanes, which are responsible for directing the flow of water towards the runner blades. By adjusting the angle of the guide vanes, the turbine can optimize its performance and adapt to different flow conditions.

The draft tube is an essential part of the Kaplan turbine, as it is responsible for converting the kinetic energy of the water into pressure energy. As the water exits the runner blades, it passes through the draft tube, gradually increasing in area. This expansion allows for the conversion of kinetic energy into pressure energy, increasing the overall efficiency of the turbine.

Finally, the runner blades are the heart of the Kaplan turbine. These blades are attached to the large boss of the runner and are designed to capture the energy from the flowing water. The runner blades are adjustable, allowing for optimal performance under varying flow conditions. Their twist along the length helps to maintain the optimum angle of attack for maximum power output.

Source here

Main Components of Kaplan Turbine:

| Component | Description |

|---|---|

| Scroll Casing | A spiral-type casing that protects internal parts and controls water flow. |

| Guide Vane Mechanism | Allows for the adjustment of guide vanes to optimize flow direction. |

| Draft Tube | Converts kinetic energy into pressure energy as water exits the runner blades. |

| Runner Blades | Adjustable blades that capture energy from flowing water and maintain optimum angle of attack. |

The combination of these components allows the Kaplan turbine to efficiently harness the energy of flowing water, making it a reliable and popular choice for hydroelectric power generation.

Working Procedure of Kaplan Turbine

The working procedure of a Kaplan turbine involves several key components and steps, which collectively enable the efficient generation of hydroelectric power. Below, we outline the process of how a Kaplan turbine operates.

Scroll Casing

The first step in the working procedure of a Kaplan turbine is the entry of water into the scroll casing. The scroll casing is a spiral-type casing that protects the internal components of the turbine, such as the guide vanes, runner blades, and other parts, from external damage. It provides a pathway for the water to flow smoothly through the turbine.

Guide Vanes

Once inside the scroll casing, the water flows through the guide vanes. These vanes are responsible for directing the water’s flow and adjusting themselves based on the power requirements of the turbine. By controlling the flow of water, the guide vanes optimize the energy extraction process.

Runner Blades

After passing through the guide vanes, the water then enters the runner blades of the Kaplan turbine. The runner blades are attached to the large boss of the runner and are designed to capture the energy of the flowing water. As the water’s reaction force causes the runner blades to rotate, the kinetic energy of the water is transferred to the turbine.

Draft Tube

Upon exiting the runner blades, the water passes through the draft tube. The draft tube gradually increases the area through which the water flows, converting its kinetic energy into pressure energy. This process helps regulate the water’s pressure and ensure a smooth discharge from the turbine. The rotation of the turbine is ultimately used to drive the generator, converting mechanical energy into electrical energy.

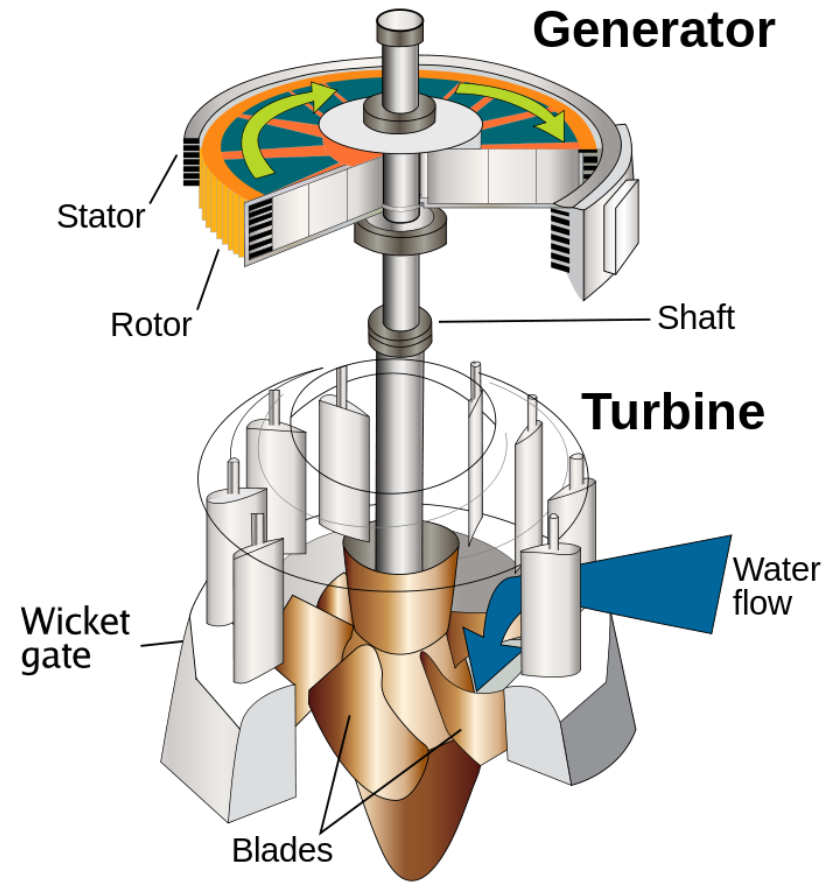

To visualize the working procedure of a Kaplan turbine, refer to the diagram below:

Kaplan Turbine Applications

The versatility and efficiency of Kaplan turbines make them well-suited for various power production applications. These turbines are particularly effective in sites with low head and high flow rates, where they can harness the power of moving water to generate electricity. Let’s explore some of the key applications of Kaplan turbines:

1. Hydroelectric Power Generation

Kaplan turbines are widely used in hydroelectric power plants around the world. Their ability to operate efficiently in low head conditions, combined with their high overall efficiency, makes them a popular choice for harnessing renewable energy from flowing water. These turbines can be found in small-scale installations as well as large-scale hydroelectric projects, playing a crucial role in global power production.

2. Irrigation Systems

Kaplan turbines are also employed in irrigation systems to power pumps and provide the necessary energy for water distribution. By utilizing the low head and high flow rates available in irrigation canals and channels, these turbines can efficiently drive irrigation pumps, helping to sustain agriculture and promote efficient water usage in agricultural practices.

3. Industrial Applications

Due to their compact size and ability to operate in a wide range of flow conditions, Kaplan turbines find applications in various industrial sectors. They can be used in industries such as paper mills, wastewater treatment plants, and manufacturing facilities where there is a need for reliable and efficient power generation. By utilizing the power of water, Kaplan turbines help industries reduce their reliance on conventional energy sources and contribute to sustainability efforts.

| Application | Key Features |

|---|---|

| Hydroelectric Power Generation | – Efficient operation in low head conditions – High overall efficiency – Suitable for small-scale to large-scale installations |

| Irrigation Systems | – Powering pumps for water distribution – Utilizing low head and high flow rates in irrigation canals and channels |

| Industrial Applications | – Compact size and versatile operation – Reliable power generation for various industrial sectors – Contribution to sustainability efforts |

Overall, Kaplan turbines offer a reliable and efficient solution for power production in a range of applications. Their adaptability to low head and high flow conditions, combined with their high overall efficiency, makes them a valuable asset in the pursuit of renewable energy solutions.

Advantages and Disadvantages of Kaplan Turbine

When it comes to hydroelectric power generation, Kaplan turbines offer several advantages that make them a popular choice. First and foremost, these turbines are highly efficient, consistently operating above 90% efficiency. This means they can effectively convert the energy from flowing water into electrical power, maximizing energy extraction and minimizing losses. The high efficiency of Kaplan turbines makes them ideal for sites with low head and high flow rates, where other types of turbines may not perform as well.

Another advantage of Kaplan turbines is their compact size. Compared to other hydraulic turbines, Kaplan turbines are smaller in size, making them easier to construct and install. This is especially beneficial in environments where space is limited. Additionally, Kaplan turbines are designed to be versatile and can operate over a wide range of flow conditions and water levels. This adaptability makes them a valuable asset in hydroelectric power generation.

However, like any technology, Kaplan turbines also have their drawbacks. One significant disadvantage is the occurrence of cavitation. Cavitation happens when there is a sudden drop in pressure in the draft tube, causing the formation of vapor bubbles in the water. These bubbles can implode, leading to erosion and damage to the turbine blades. To mitigate cavitation, the design of the turbine and draft tube must be carefully optimized. The use of materials such as stainless steel for the runner blades can also help reduce the risk of cavitation.

Advantages of Kaplan Turbine

- High efficiency, operating above 90%

- Compact size, suitable for limited space environments

- Versatility in operating over a wide range of flow conditions

Disadvantages of Kaplan Turbine

- Cavitation, which can lead to erosion and damage

In conclusion, Kaplan turbines offer several advantages in hydroelectric power generation, including high efficiency, compact size, and versatility. However, they are also susceptible to cavitation, which can pose challenges if not properly addressed. By optimizing design and using appropriate materials, the disadvantages of cavitation can be mitigated, allowing Kaplan turbines to continue playing a significant role in renewable energy solutions.

Kaplan Turbine Variations

The Kaplan turbine, although commonly known as a propeller turbine, has several variations that offer different advantages in various applications. These variations include propeller turbines, bulb turbines, and tubular turbines.

Propeller turbines, also known as fixed-blade Kaplan turbines, have non-adjustable blades and are typically used in applications with a limited range of flow and power. They offer simplicity and reliability, making them suitable for smaller-scale hydroelectric projects.

Bulb turbines, on the other hand, are installed within a bulb-shaped structure that encloses the turbine. This design allows for higher efficiency by reducing energy losses. Bulb turbines are commonly used in low-pressure hydropower sites, such as river and tidal currents, where they can harness energy effectively.

Tubular turbines, the third variation, have their generator located outside the water passage. These turbines can be equipped with either variable or fixed blades, offering flexibility in power output. Tubular turbines are often used in high-head applications and are known for their high efficiency and compact design.

Variations of Kaplan Turbine

| Variation | Description | Applications |

|---|---|---|

| Propeller Turbines | Non-adjustable blades | Small-scale hydroelectric projects with limited flow and power requirements |

| Bulb Turbines | Installed within a bulb-shaped structure | Low-pressure hydropower sites, such as river and tidal currents |

| Tubular Turbines | Generator located outside the water passage | High-head applications requiring high efficiency and compact design |

Each variation of the Kaplan turbine is designed to meet specific requirements and optimize power generation in different flow conditions. The choice of variation depends on factors such as site characteristics, available head and flow rates, and desired power output.

Sources:

- Hydropower: Renewable Energy Solution for Power Generation – W. Wojciechowski

- Hydraulic Turbines: Design and Application – R. K. Turton

- Hydropower Engineering Handbook – John S. Gulliver and Pow Choon Tan

Efficiency and Performance of Kaplan Turbine

When it comes to efficiency and performance, Kaplan turbines are at the forefront of hydroelectric power generation. These turbines are designed to deliver exceptional efficiency, typically above 90%, making them highly effective in converting the kinetic and potential energy of flowing water into electricity. The ability of Kaplan turbines to maintain a high level of efficiency across a wide range of flow conditions makes them particularly suited for sites with low head and high flow rates.

One key advantage of Kaplan turbines is their adaptability to varying flow conditions. Whether the water flow is high or low, Kaplan turbines can efficiently harness the available energy, ensuring consistent power production. This flexibility makes them a reliable choice for regions with fluctuating water levels or unpredictable flow rates.

Moreover, Kaplan turbines have proven their performance capabilities in numerous hydroelectric power plants around the world. Their advanced design, which includes adjustable runner blades and guide vanes, allows for optimal energy extraction from the flowing water. This results in excellent turbine performance and maximized power output, contributing to the overall efficiency of the hydroelectric system.

| Advantages | Disadvantages |

|---|---|

|

|

The high efficiency and performance of Kaplan turbines make them an integral part of renewable energy solutions. Their reliability, adaptability, and consistent power generation capabilities position them as a key player in the field of hydroelectric power, contributing to the global efforts towards a sustainable future.

The Development and Inventor of Kaplan Turbine

The Inventor: Viktor Kaplan

The Kaplan turbine, a key component in hydroelectric power generation, was developed by Austrian professor Viktor Kaplan in the early 20th century. In 1912, Kaplan obtained a patent for an adjustable blade propeller turbine, which laid the foundation for his groundbreaking work. In 1919, he installed a demonstration unit, and it wasn’t until 1922 that Voith introduced an 1100 HP Kaplan turbine for commercial use. Since then, Kaplan turbines have gained widespread acceptance and have become an integral component of hydroelectric power plants worldwide.

The Development of Kaplan Turbine

Kaplan’s invention revolutionized the field of hydropower. Before his turbine design, propeller-type turbines could not efficiently operate under varying flow conditions. Kaplan’s solution involved combining automatically adjusted propeller blades with wicket gates, enabling these turbines to achieve high efficiency over a wide range of flow and water levels. The resulting Kaplan turbine, also known as the propeller turbine, surpassed the performance of its predecessors, making it ideal for hydroelectric power generation.

The Legacy and Impact

Viktor Kaplan’s groundbreaking work in turbine design continues to shape the renewable energy landscape today. Kaplan turbines are known for their efficiency, adaptability to different flow conditions, and ability to operate at low head and high flow rates. As the demand for clean and sustainable energy solutions grows, Kaplan turbines are set to play an increasingly significant role in meeting these needs. The ingenuity of Viktor Kaplan’s invention has paved the way for the development of renewable energy solutions that harness the power of water to generate electricity.

Table: Comparing Kaplan and Other Turbine Types

| Turbine Type | Main Advantages | Main Disadvantages |

|---|---|---|

| Kaplan | High efficiency over a wide range of flow conditions | Potential for cavitation in draft tube |

| Francis | Efficient at medium head and moderate flow rates | Less efficient at low head and high flow rates |

| Pelton | Highly efficient at high head and low flow rates | Limited operating range |

| Propeller | Suitable for low head and high flow rates | Fixed blade design limits adaptability |

Current Research and Advancements in Kaplan Turbines

The field of Kaplan turbines is constantly evolving with ongoing research and advancements aimed at further improving their efficiency and performance. One area of focus is the use of computational fluid dynamics (CFD) analysis to optimize the design and maximize energy extraction. CFD allows researchers to simulate and study the fluid flow patterns within the turbine, enabling them to identify areas for improvement and make design adjustments accordingly.

Through CFD analysis, researchers can evaluate the impact of different blade shapes, angles, and materials on the turbine’s performance. This information helps in developing more efficient and durable Kaplan turbines with higher power output. Furthermore, CFD analysis aids in minimizing energy losses, increasing overall operating efficiency, and reducing maintenance costs.

Another area of research is improving fish passage through Kaplan turbines to mitigate ecological impacts. Efforts are underway to develop innovative turbine designs that provide safe passage for fish while maintaining turbine efficiency. By incorporating fish-friendly features such as bypass channels, screens, or specialized guide vane mechanisms, researchers aim to minimize fish mortality and ensure the sustainability of aquatic ecosystems.

| Advancements in Kaplan Turbines | Research Areas |

|---|---|

| Enhanced efficiency and power output | Computational fluid dynamics (CFD) analysis |

| Fish-friendly turbine designs | Fish passage optimization |

| Improved material selection | Enhancing turbine durability |

| Reduced maintenance costs | Optimizing turbine performance |

Advancements in materials and manufacturing techniques are also being explored to enhance the performance and durability of Kaplan turbines. Researchers are investigating the use of advanced materials, such as carbon composites and alloys, which offer improved resistance to corrosion, erosion, and fatigue. In addition to materials, manufacturing processes like 3D printing and precision machining are being explored to achieve more precise and efficient turbine components.

Kaplan Turbines in Wave Energy Generation

Kaplan turbines have expanded their applications beyond traditional hydroelectric power generation and are now being utilized in the field of wave energy generation. One notable example of this is the Wave Dragon, a wave energy converter that incorporates Kaplan turbines to harness renewable energy from ocean waves.

By adapting Kaplan turbines to suit the unique conditions of offshore wave energy systems, the Wave Dragon maximizes the energy extraction potential from the ebb and flow of waves. This innovative approach to wave energy generation helps to diversify our renewable energy solutions and tap into the vast potential of the world’s oceans.

The integration of Kaplan turbines in wave energy systems allows for the conversion of the kinetic energy present in ocean waves into usable electrical power. As the waves pass through the Wave Dragon, the kinetic energy is harnessed by the rotating Kaplan turbines, which then drive generators to produce clean and sustainable electricity.

Advantages of Kaplan Turbines in Wave Energy Generation

- Efficient conversion of wave energy: Kaplan turbines are known for their high efficiency, enabling effective extraction of energy from ocean waves.

- Adaptability to varying wave conditions: Kaplan turbines can adjust their blade angles to optimize energy conversion in different wave heights and frequencies.

- Versatile placement: Kaplan turbines can be installed on offshore platforms, floating structures, or submerged systems, allowing for flexible deployment options.

- Minimal environmental impact: Wave energy systems utilizing Kaplan turbines have minimal impact on marine ecosystems, as they do not require extensive dam constructions or disrupt natural water flows.

The incorporation of Kaplan turbines in wave energy generation represents a promising advancement in the field of renewable energy. These turbines offer a reliable and efficient means of harnessing the power of ocean waves, contributing to the global effort to reduce dependency on fossil fuels and mitigate climate change.

Where to buy Kaplan turbines?

Some of the manufacturers can be found here and include:

- De Pretto Industrie: An Italian company that produces Kaplan turbines for power generation

- GE Renewable Energy: A multinational company that produces Kaplan turbines with oil-free hubs and self-lubricating brushes for hydroelectric power stations

- Kirloskar: An Indian company that produces Kaplan turbines for power generation

- Neftekamsk Machinery Plant LLC. (NKMZ): A Russian company that produces Kaplan turbines for power generation

Conclusion

Kaplan turbines have revolutionized hydroelectric power generation, providing a highly efficient and adaptable solution for harnessing renewable energy from water sources. These turbines, developed by Austrian professor Viktor Kaplan in 1913, combine automatic propeller blades and wicket gates to achieve high efficiency over a wide range of flow and water levels.

With their ability to operate at low head and high flow rates, Kaplan turbines have become a valuable tool in hydroelectric power production. They offer a compact size and ease of construction compared to other hydraulic turbines, making them a popular choice for renewable energy solutions.

As research and advancements continue, Kaplan turbines will play a significant role in meeting the increasing demand for clean and sustainable energy. Their high efficiency and adaptability to various flow conditions make them a key component in the development of hydroelectric power and the realization of a greener future.

FAQ

How do Kaplan turbines work?

Kaplan turbines work by utilizing the kinetic energy and pressure energy of water to efficiently rotate the turbine blades in a hydroelectric power station. They combine automatically adjusted propeller blades with wicket gates to achieve high efficiency over a wide range of flow and water levels.

What are the main components of a Kaplan turbine?

The main components of a Kaplan turbine include the scroll casing, guide vane mechanism, draft tube, and runner blades. The scroll casing protects the internal parts of the turbine, while the guide vane mechanism controls the flow of water. The draft tube is used to discharge water from the runner, and the runner blades are adjustable to optimize power output.

How does the working procedure of a Kaplan turbine start?

The working procedure of a Kaplan turbine starts with water entering the scroll casing and flowing through the guide vanes. The guide vanes direct the water through a 90-degree turn, causing it to flow axially through the runner blades. The water’s reaction force rotates the runner blades, transferring energy to the turbine.

What are the advantages and disadvantages of Kaplan turbines?

The advantages of Kaplan turbines include their ability to operate efficiently at low head and high flow rates, their compact size, and high overall efficiency. However, they have a disadvantage known as cavitation, which can be reduced through design optimization.

What are the different variations of Kaplan turbines?

There are several variations of Kaplan turbines, including propeller turbines, bulb turbines, and tubular turbines. Each variation offers different advantages and is designed to meet specific requirements.

How efficient are Kaplan turbines?

Kaplan turbines are known for their high efficiency, typically above 90%. They maintain their efficiency over a wide range of flow conditions, making them suitable for sites with low head and high flow rates.

Who invented the Kaplan turbine?

The Kaplan turbine was invented by Austrian professor Viktor Kaplan in the early 20th century.

What current research is being done on Kaplan turbines?

Current research on Kaplan turbines focuses on improving efficiency through computational fluid dynamics analysis and developing designs for better fish passage. Advances in materials and manufacturing techniques are also being explored.

How are Kaplan turbines used in wave energy generation?

Kaplan turbines have been adapted for use in offshore wave energy generation systems, such as the Wave Dragon. These turbines harness energy from ocean waves and contribute to the development of renewable energy solutions.